Topglass

Topglass® Ultima

ULTIMATE PROTECTION OF PROPERTY AND OCCUPANTS

- Offers superior protection by blocking 99% of harmful UV rays, ensuring the safety and comfort of the space underneath.

Features UVAS+ that uses nano-technology and reduces UV penetration. - Maintains its color integrity over time, reducing fading and preserving its aesthetic appeal.

- Ultimate light transmission and delay in colour chang

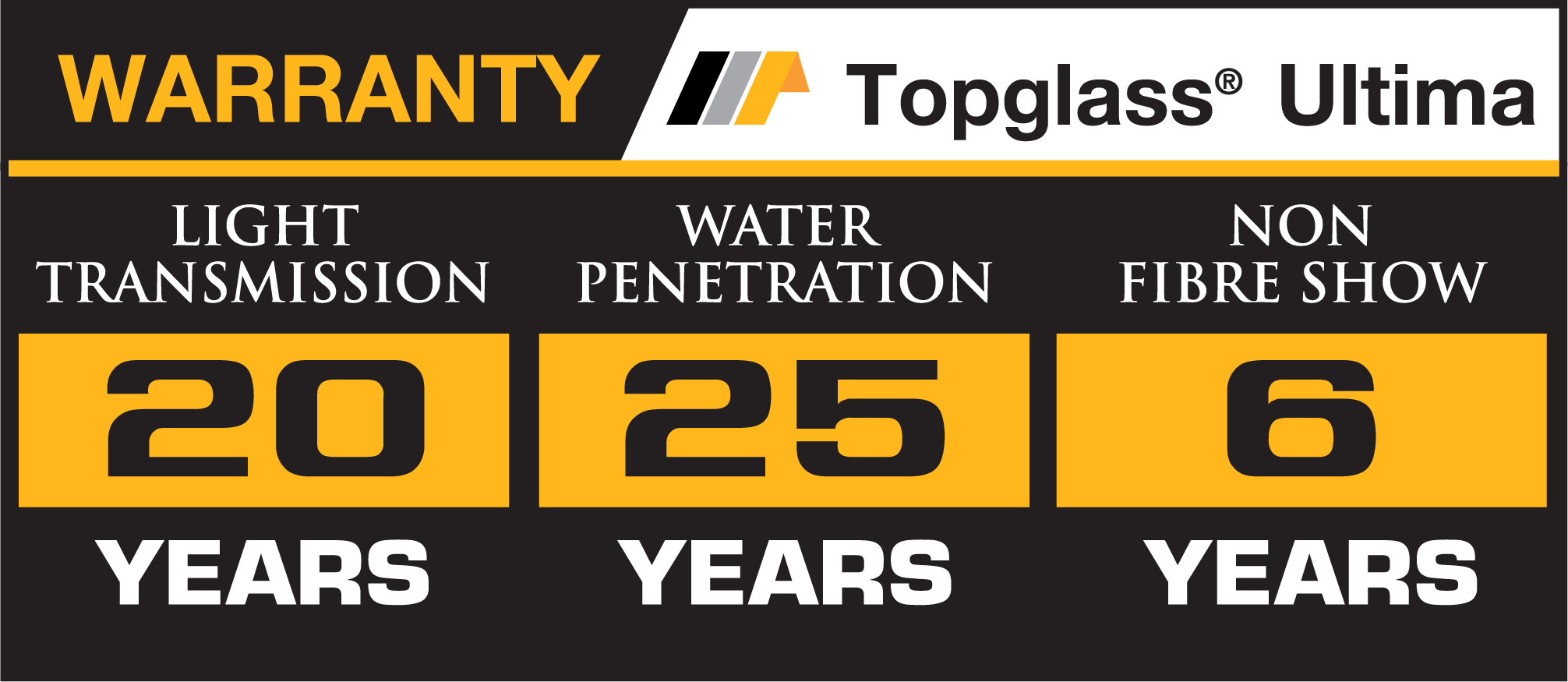

- 20 Years warranty

- 25 years water penetration warranty

- 6 years non-fibre show warranty

Ultraviolet Impeding Coating Plus – UVIC+

UVIC+ is tougher and thicker coating from the original UVIC feauring

an increase in thickness of 50% to 30 microns

Advantages and Benefits of these new features are

- Full UV Protection – ultimate protection of property and people

- Non-delamination of coating – full cure of the product result in permanent lamination of the UVIC+ throughout it’s life time

- A 50% increase in Surface Protection thickness – result in a tougher and longer lasting surface protection of the product and also delay in colour change

Ultraviolet Absorber Stabilizer Plus – UVIS+

UVIS+ is a new breakthrough whre it is now able to pack more UV absorber into resin through nano technology reducing the size of each absorber causing it to cross-link allowing more UV Beingabsorbed and less UV being pass through.

Advantages and Benefits of these new features are

- Higher absorption of UV – slows down changes in of product

- Increase light transmission lifespan – more light for the propety

- Natural skylight for roof and wall for commercial and industrial buildings.

- Public and private facilities requiring ample natural lightings.

- Air-conditioned buildings such as supermarkets and malls.

- Food processing facilities.

- Warehouses and retail outlets storing food and fresh produce.

- Bulk paper storage areas.

- Barcol Hardness (Barcol Impressor Model no.GYZJ.934)

- Exposure Ultraviolet lamps M/C (Compile AS/NZS 2433)

- Spectrophotometer (Model no. CM-3600A for measurement L,A,B)

- Diffuse Light Tranmission M/C (AS/NZS 4257.4)

- Impact Resistant M/C (Compile AS/NZS 4257.6)

- QUV Accelerated Weathering Chamber UVB313 (ASTM G53)

- Microscope Camera

Raw Material

Utilizing high-quality resin and incorporating UV Absorber Plus (UVAS+), a substance produced with nanotechnology, helps absorb UV radiation effectively, preventing it from passing through the underside of the sheet surface.

Top Coating

EXO-SET 205, a high-quality gel coating layer produced with advanced technology from New Zealand, has a thickness of 100 microns to effectively protect against UV radiation. It is combined with a Solar Protective Coating to reflect heat and prevent it from entering the building.

Fiberglass

High quality fiberglass strands are used to enhance the strength of translucent sheets, ensuring long-lasting durability and resistance to cracks, shrinkages and water leakages.

Bottom Film

Our final translucent sheet product using CHP Production Technology will result in a fully cured product. Hence the bottom film is no longer required and will be removed to prevent delamination.

Production Process

Our production process utilizes advanced CHP (Cumene Hydroperoxide) technology, which operates at higher temperatures and incorporates a longer production line compared to the traditional MEKP method. As a result, our product is fully cured and highly durable.

Thickness / Weight

Thickness = 1.5 mm.

Weight = 2400 gsm.

Color

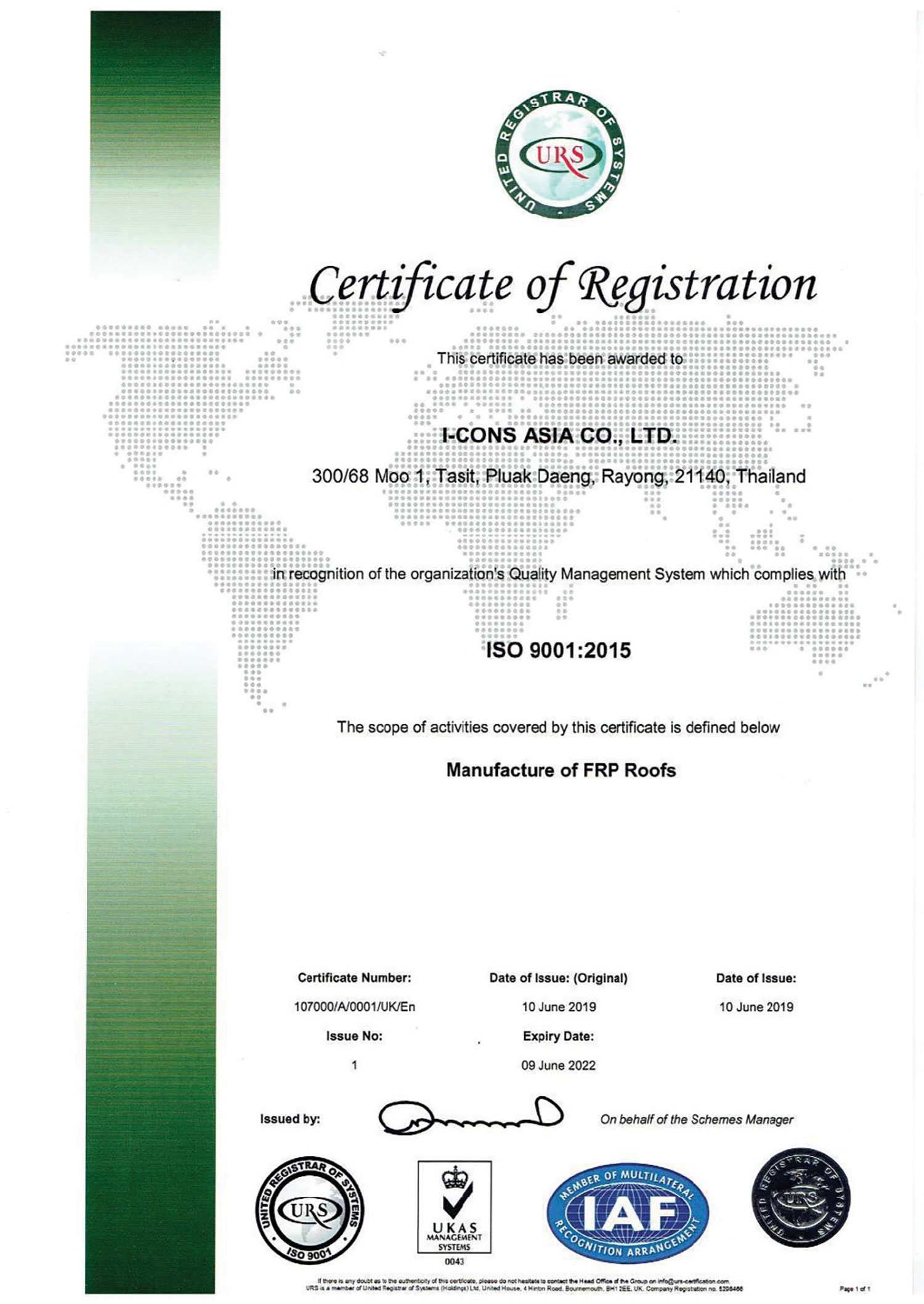

Certifications

- Received AS/NZS 4256.3:2006 standard, Client BMP NO. 535535, a standard from Australia, acknowledged in over 90 countries worldwide.

- Certified for manufacturing quality by BSI Group from Australia, an organization certifying product standards accepted in 150 countries worldwide.

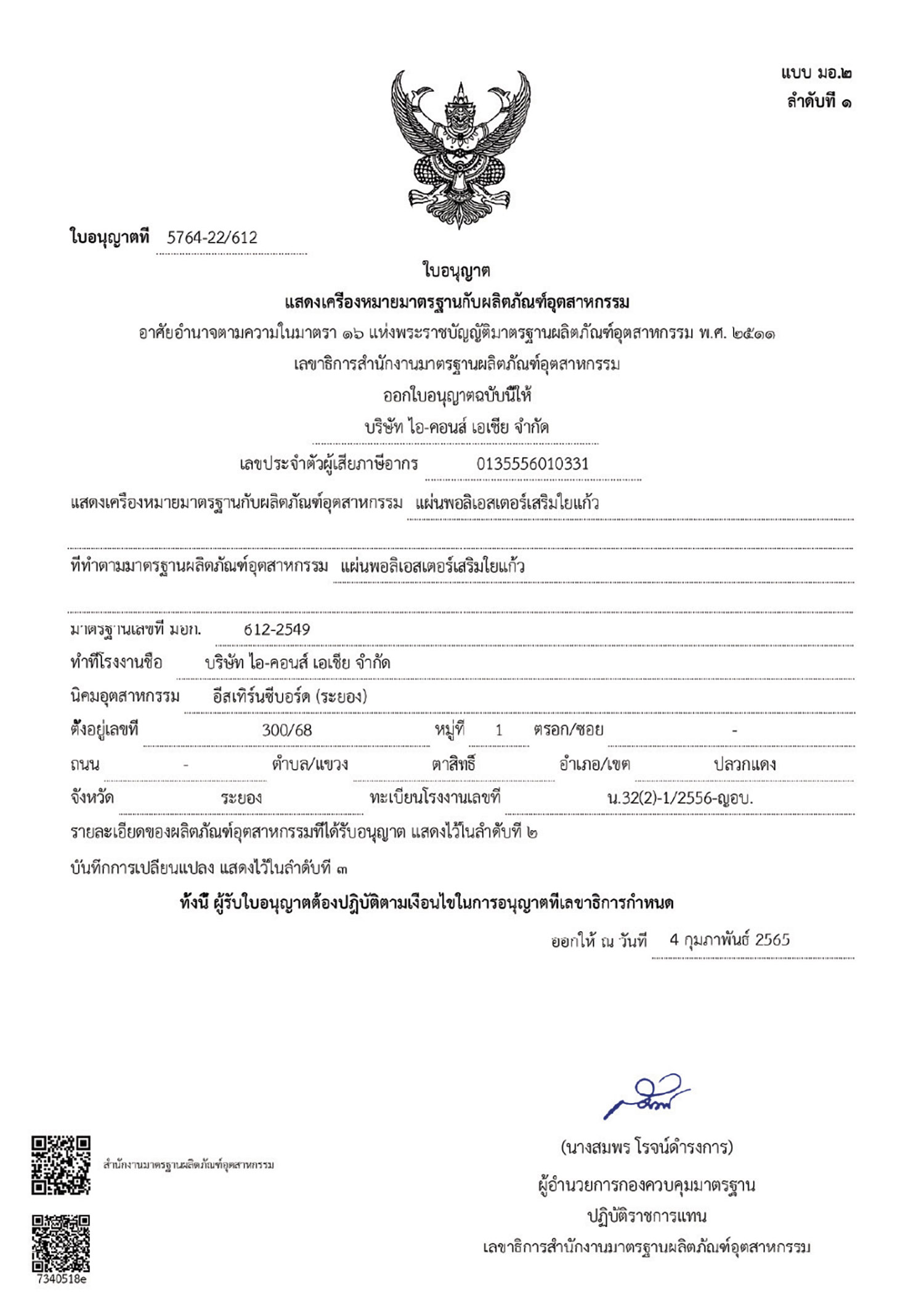

- Received the Thai Industrial Standard, TIS 612-2549, from Thailand.

ISO 9001 : 2015

TIS 612 – 2549

AS/NZS 4256.3 : 2006