FIX-PLUS

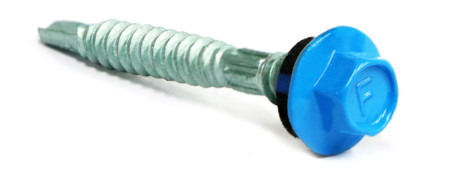

FIX-PLUS self-drilling screws is designed for fastening metal roofing sheets. FIX-PLUS comes with high quality Dekseal® TrueBlue® EPDM Seal. Surpassing 1,000 hours of salt spray test and 15 cycles of Kerternich tests, FIX-PLUS fasteners comes with a 10-year warranty and is suitable for use with AZ90 metal sheets.

FIX-PLUS Features

- Patented Sabre Point provides reliable and fast drilling penetration.

- Optimal drill point designed for both metal and timber applications

- Enhanced durability against corrosive elements such as salt spray and chemicals.

- High quality Dekseal® TrueBlue® EPDM Seal with a lifespan of up to 20 years.

- Shank protection protects the shank of the screw from damages and avoids scratches that will cause rust in long term.

- High thread helps lift the edge of the hole to rise upwards and be embedded into the EPDM seal thus preventing water leakages and overdriving.

- Rust-proof warranty of 10 years.

- Suitable for use with AZ90 coated metal sheets

PRODUCT FEATURES

Screw Head

- Screw head securely locks into the block, ensuring it doesn’t loosen during operation.

- Color options match standard and custom metal sheet colors, enhancing aesthetics and increasing resilience against UV and corrosion damage.

Shank Protection

Smoothing the edges of the metal sheet prevents scratching the screw’s color and the roofing panel, ensuring the coating’s integrity and preventing screw loss issues.

High Thread

Sabre Point

- Available in various materials: steel, special thickness steel, wood, and self-tapping.

- Sharp, fast-drilling spade point designed for user ease. Specifically engineered to suit each material type, ranging from steel thickness of 0.4mm to textured steel of 12.5mm.

- Specially designed Sabre Drilling Point for thick steel, capable of drilling up to 20mm.

- Pointed screw tip designed for wood applications.

Dekseal® TrueBlue® EPDM Seal

Each FIX-IT fasteners is equipped with a premium EPDM TrueBlue® seal by DEKS Industrial.

- Non-conductive and securely fastened without leakages.

- Prevents electro-galvanic corrosion

- High flexibility and meets the AS3566 standards

Dekseal® TrueBlue® EPDM Seal is highly durable and comes with a 20-year warranty.

PERFECT SCREW HEAD COLOR MATCHING

With over 300 standard colors and custom options available, FIX-IT offers an appealing low MOQ and fast lead time. The color paint features a special formulation designed to last a long time under strong UV conditions.

Coating layer CLIMATEX-3 CORROSION PROTECTION COATING

Heat Treatment

The FIX-IT screws are manufactured from standard-grade steel, AISI1022, and undergo hardening processes. The surface hardness is meticulously controlled to suit operational needs while maintaining flexibility to accommodate roof sheet expansion.

Polymer Barrier Coat

The external coating consists of epoxy polymer resin, providing durability against heat, moisture, chemical oxidation, and abrasions. The coating thickness is 25 microns, ensuring enhanced protection and longevity for the screws.

Screw Sizes and Sabre Points

Sabre Points for roofing sheet screws

Name : FIX-PLUS 12-14×48 HHS

Gauge : 12

T.P.I. : 14

Drill Point : TEK Sabre Point

Length : 48 mm.

Name : FIX-PLUS 12-14×55 HHS

Gauge : 12

T.P.I. : 14

Drill Point : TEK Sabre Point

Length : 55 mm.

Name : FIX-PLUS 12-14×65 HHS

Gauge : 12

T.P.I. : 14

Drill Point : TEK Sabre Point

Length : 65 mm.

Sabre Points for Valley Fixing & Stitching

Name : FIX-PLUS 10-16×16 HS

Gauge : 10

T.P.I. : 16

Drill Point : TRP

Length : 16 mm.

Name : FIX-PLUS 12-14×20 HS

Gauge : 10

T.P.I. : 14

Drill Point : TEK

Length : 20 mm.

Name : FIX-PLUS 15-15×20 HS

Gauge : 15

T.P.I. : 15

Drill Point : TEK

Length : 20 mm.

FIX-PLUS MEETS CLASS-3 AS3566 ACCELERATED TESTING STANDARDS

1. Salt Spray Test in accordance with AS2331.3.1 – 1,000 hrs.

(less than 5% red rust)

The salt spray test is conducted according to AS2331.3.1 for a duration of 1,000 hours.

2. Kesternich Test in accordance with DIN 50018 – 15 cycles

(less than 5% red rust)

The acid rain test is performed according to DIN 50018 with a duration of 15 cycles.

3. Humidity Test 100% Humidity in accordance with ASTM D2247 – 1,000 hrs

(no blister size S3 or larger)

The salt spray test is conducted according to AS2331.3.1 for a duration of 1,000 hours.

4. Ultraviolet Test in accordance with ASTM G154 – 2,000 hrs

(no cracking, flaking and peeling)

The ultraviolet (UV) exposure test is performed according to ASTM G154 for a duration of 2,000 hours.

10-Year Rust Proof Warranty

Characterised by fall-out from adjoining severe industrial environments or where small industries lead to significant industrial fall-out. Generally includes other service buildings located near heavy industrial plants, including out-buildings of the plant itself.